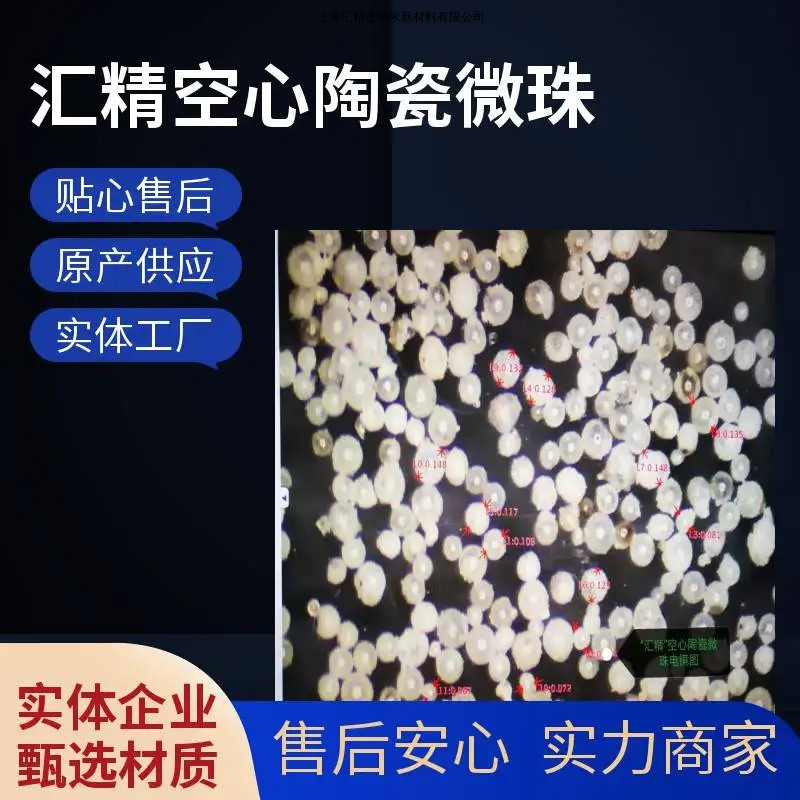

Huijing hollow ceramic microspheres are produced using high-quality raw materials and advanced production processes. The hollow ceramic microspheres are closed-cell spherical particles with inert gas inside the spheres. They have low thermal conductivity, low wall breakage rate, low specific gravity, uniform particle size distribution, low impurity content, and pure and stable color.

Purpose:

As a filler, it can be used in industries such as thermal insulation, fire-resistant coatings, wood-plastic products (wood substitutes, imitation wood), polymers, adhesives, putties, fiberglass, electrical insulation materials, composite materials, refractory materials, thermal insulation materials, waterproof coatings, building materials, casting risers, oilfield cementing, as well as aerospace, marine, automotive, and pesticide carriers.

Unique performance:

1. Improve rheological properties, reduce viscosity, and lighten product weight

Hollow ceramic microspheres have excellent flowability, which can reduce viscosity and improve rheology and flowability. The specific gravity of 0.3-0.4 can greatly reduce the weight and cost of the product, making it a new type of functional filling material for unsaturated resins.

2. High filling capacity, low release of adhesive dosage

Hollow ceramic microspheres are spherical in shape and have the smallest specific surface area, so the adhesive used is less than that of general fillers.

3. Chemical stability

The material composition of hollow ceramic microsphere aluminum silicate gives it strong chemical stability.

4. Fire resistance

Hollow ceramic microbeads have a melting point above 1400 degrees and can be used as a good material for fireproof coatings, especially suitable for expansion type fireproof coatings.

5. Thermal insulation and sound insulation properties: The thin-walled sealed hollow spherical structure gives it unique insulation, heat insulation, and sound insulation effects, and is widely used in thermal insulation and sound insulation coating products.

6: Pesticide carrier: high floating rate, environmentally friendly, recyclable and reusable.

7: Casting riser: light weight and high temperature resistance of 1350 ° C

8: Oilfield production cementing